Shipping and delivery management in warehouses

Shipping and delivery management is a crucial aspect of warehouse operations. The process involves the planning, organizing, and execution of delivery activities, including the preparation of goods for shipment, transportation, and delivery to the intended destination. Effective warehouse shipping and delivery management requires reliable inventory tracking systems, managing orders, and coordinating shipping activities. It ensures that the correct goods are shipped to customers at the right time, minimizing errors and delays. Using the right tools and strategies, warehouse managers can streamline their shipping processes, reduce costs, and improve customer satisfaction.

The main components of shipping and delivery management include:

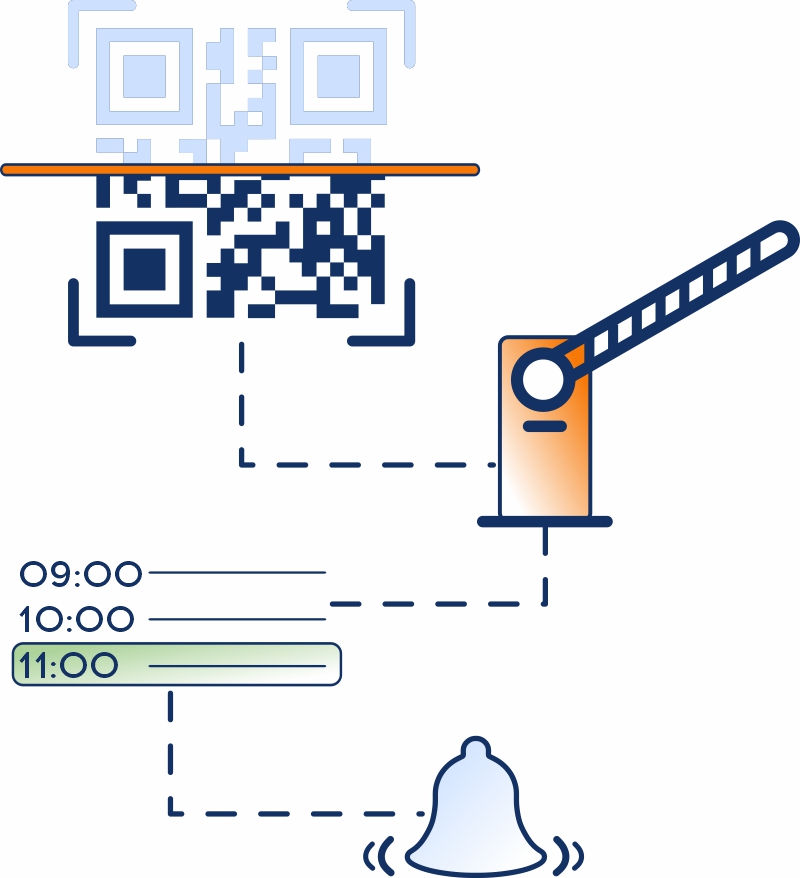

Time slot management is an essential part of logistics that plays a significant role in ensuring the timely delivery of goods. It involves the allocation of specific time slots for the loading and unloading of goods. This process is crucial for managing the flow of goods in and out of the warehouse, especially during peak periods. By allocating specific time slots, warehouse managers can ensure that the loading and unloading processes are well-organized and efficient.

In time slot management, each delivery or pickup is assigned a specific time slot based on the warehouse staff's availability, delivery vehicles, and loading and unloading docks. It ensures that the warehouse can handle the workload efficiently without any delays. It also helps optimize resource use, such as labor and equipment.

One of the key benefits of time slot management is that it helps to reduce waiting times for delivery vehicles. It, in turn, helps reduce congestion in the warehouse and roads. It also minimizes the risk of late deliveries, resulting in dissatisfied customers. Truck drivers, on average, face a wait time of 2.5 hours at loading docks, with nearly 63% reporting wait times of over three hours on each visit. These prolonged idle periods, often unpaid, disrupt their schedules, resulting in decreased earnings. In the U.S., while the average waiting period is 2.5 hours, it exceeds 6 hours in 9.3% of cases.

Time slot management solves problems:

Our platform offers a comprehensive solution for efficient order management that helps businesses automate their processes and reduce errors. We build practical tools for companies seeking to optimize their order management processes and improve their bottom line.

Access control systems are an essential warehouse management component for the delivery and shipment of trucks. These systems provide a secure way of managing access to warehouse areas, ensuring that only authorized delivery trucks and personnel can enter specific areas.

The delivery or shipment process becomes a well-orchestrated scenario with an access control system. The system verifies the credentials of the truck, ensuring it's on the approved list and has the right to enter. Once the green light is given, the barriers lift, and the cargo enters the designated area, ready to unload.

Before developing the system, we model the entire sequence of events, considering the peculiarities of your territory, technical support, regulations, and experience. We consider all positive and negative scenarios in the operation of the control system. Alternatives are worked out for the negative scenarios.

Signaling systems in warehouses play a critical role in guiding and directing truck drivers to their designated loading and unloading areas. These signals help minimize the time taken for loading and unloading and improve the operations' safety.

Various signaling systems are used in warehouses for this purpose. Some common examples include traffic signals, automated signs, and flashing lights. These signals are placed at strategic locations within the warehouse and are designed to provide clear and concise instructions to truck drivers.

The signaling systems can also be integrated with warehouse management software to provide real-time updates on the status of loading and unloading activities. It helps reduce wait times for truck drivers and ensures the entire process is completed as efficiently as possible.

In addition to the signaling system, our platform can integrate various driver notification systems, from specialized pagers to messages to convenient messengers.

Combining the signaling system with warehouse time slot management can offer several benefits. By integrating these two systems, warehouse managers can have a comprehensive solution to manage their shipping and delivery processes better. The signaling system can provide real-time updates on the progress of loading and unloading activities, helping warehouse managers track the movement of goods and reduce waiting times for delivery vehicles. Additionally, this integration can improve overall resource utilization, as warehouse staff can be better prepared for the arrival of delivery vehicles and ensure they are ready to load or unload goods promptly. Combining signaling systems with time slot management can help warehouses increase their efficiency, reduce costs, and improve customer satisfaction.